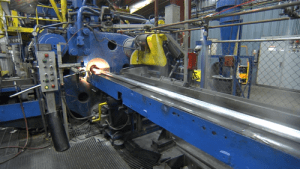

Aluminium Extrusions is a term that refers to how aluminium is shaped. An extrusion is produced by pushing aluminium billet heated to 600 degrees celsius through a steel die.

The result in the extruded material emerging as a perfectly replicated cross section of the die pattern.

Why is Extruded Aluminium Strong?

The Extrusion process gives a smooth surface finish and often improves the tensile strength of the material. Aluminium is the most commonly extruded material and can be made into almost any shape imaginable.

How are Aluminium Tubes extruded?

We are often asked how aluminium hollow sections (such as tube) can be extruded – given that there is no way to hold the centre barrier of the die. In this case the die is made in a block shape with depth – beginning first with a shape profile that supports the middle section. The die shape then changes internally along its length into the final shape, with the suspended centre pieces supported from the back. The material flows around the supports and fuses together to create the desired closed shape.

What are Aluminium Extrusions Used For?

Aluminium extrusions are very commonly used to create window and door systems, and can be found in thousands of applications for the building and manufacturing industries. ATC’s most popular extrusion is the angle shape that we stock in plain mill finish, pre anodised and pre powder coated in black and white. These shapes are a simple right angle that can have sides of equal or unequal length and come in a variety of different wall thicknesses.

Other popular aluminium extrusions include shapes such as a square hollow (or square tube), round tube and rectangular hollow. We also carry solid sections such as square, round and flat bars. ATC produces custom shapes for many of our customers. However please bear in mind that aluminium extruding should be considered a volume process due to the cost of new dies – ranging from $500 to $3,000 – and require a minimum production run of at least 250kg’s of aluminium billet.

What is the difference between drawn and extruded aluminium?

Drawing aluminium is a similar process to extruding aluminium. The main difference is how the aluminium is shaped by the die. Drawing aluminium means process uses the tensile strength of the material to pull it through the die, limiting the amount of variation within the shape.

ATC’s aluminium supplies include stock of drawn tube – useful for when minimal variation is required such as when tubes need to slide into one another. Stock is available in anodised and mill finish.

After being extruded or drawn, the aluminium sections are allowed to cool, cut to the desired lengths then baked in ovens at varying temperatures and for varying lengths of time to create the desired temper (or hardness). The temper scale starts at T0 and rises to T6 for structural applications.

After tempering, the aluminium can be further treated by adding a coating (usually anodising or powder coating), or sold raw – i.e. “mill finish”.

Below is a brief animated video on the Aluminium Extrusion process

For more general information about aluminium extrusions and tempers click here, or for a technical overview of international aluminium standards click here.