Did you know 25% of all the aluminium is used in the construction industry? In the early twentieth century, aluminium was too expensive and not produced in sufficient volumes to use in construction, but that changed in the 1920s, when the electrolysis process reduced the cost of aluminium by 80%. The metal became extremely popular for finishing roofs and domes and for use in drains and wall panels, as well as for decorative purposes.

Here are the top 10 most common uses for aluminium in the construction industry today:

1. Aluminium Skirting

Using aluminium for skirting you’ll find there are no blemishes, knots or warping as is possible with timber. Aluminium skirting takes a lot of punishment and will not crack, splinter, warp or rot if it gets wet. It’s great value for money and is easy to replace when required.

Aluminium skirting can be made in any colour – in fact ATC stocks a range of sizes and finishes including anodised, as well as powder coated in black and white. Custom colours can also be arranged.

2. Roofs

Aluminium is a great roofing material coming in the form of tiles and shingles in Australia. Being extremely resistant to corrosion. It’s lightweight in comparison to other materials and its strength-to-weight ratio is among the highest of the “common” metals–that’s why airplane designers use aluminium for air frames. This lightness and thinness also means aluminium roofing material stores very little heat and also becomes cool quickly once it stops receiving direct sunlight. Aluminium is quite malleable, allowing it to be configured into complex profiles and as for life span – it will probably outlive all of us.

3. Cladding

Aluminium cladding has received an unfairly bad reputation in recent times for being combustible – but this occurred thanks to constructors using low quality and non-compliant material. Pure aluminium flat sheets will not catch fire, looks great and has excellent thermal properties. For example, aluminium sheet with reflective foil covering protects premises from cold temperatures four times better than 10 cm thick brick facing or 20 cm thick stone masonry. That is why it is widely used in the coldest areas of the world like Siberia.

Solid aluminium cladding can be used in so many creative ways and is 100% fire rated

4. Window and door frames

Aluminium is far and away the installer’s material of choice when it comes to windows and door frames. Aluminium windows are a perfect choice for modern houses and high-rise builds, though their sleek style can also be tailored to treat period homes. Aluminium frames can be powder coated to any colour and the very high strength-to-weight ratio means that there’s less aluminium needed to withstand large amounts of glazing and wind deflection compared to other materials.

Aluminium double glazed window frame with thermal break.

5. Solar panels

Aluminium is used for the frames and fixing systems for solar panels as well as inside the panels themselves. Being light in weight, high in strength, and able to withstand rooftop conditions without corroding, aluminium is the perfect material for this use.

6. Staircases and safety ramps

Once again, the light weight combined with high strength of aluminium and the fact that it will not rot or rust means that it is the perfect material for staircases and ramps. Aluminium is cheaper than steel or wrought iron, despite possessing the same strength and durability benefits and requires very little maintenance in both wet and dry conditions.

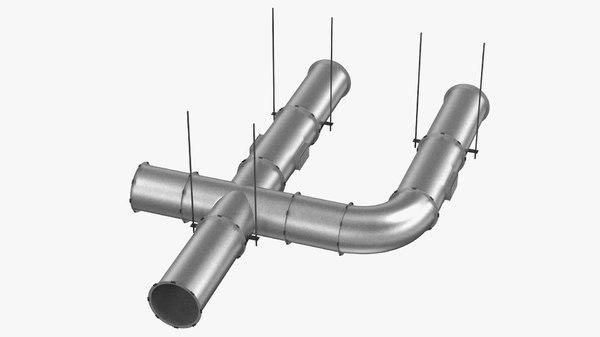

7. Air conditioning systems

Aluminium tubing is rapidly becoming the tube material of choice in HVAC and air conditioning applications because it is cheaper, lighter and more recyclable than copper. Although it is true that aluminium is only 50% as efficient in conducting heat, the difference is negligible when it comes to heat transfer performance. Also, aluminium is immune to “formicary corrosion” – a long standing problem with copper tubing in air conditioning systems caused by a chemical reaction to lubrication oils.

Aluminium air conditioning ducted system.

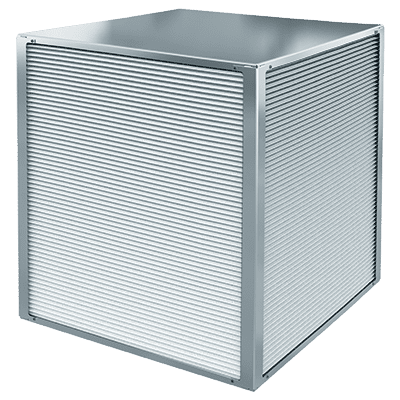

8. Heating systems / exchangers

Aluminium with its high thermal conductivity passes on heat rapidly – so you and your house get warmer faster! If you’ve ever filled a hot water bottle, it can be surprising how cool it can feel at first, even when it’s just been filled with hot water. But the heat does get through eventually. If it were made of aluminium rather than rubber, it would warm up in no time. Aluminium heat exchangers are also much quieter, lighter, less affected by corrosion and cheaper than stainless steel.

9. Furniture

Aluminium is of course fantastic for outdoor furniture being durable and light, and able to be formed into any shape. You’ll also find some amazing looking modern furniture made with aluminium frames and fittings. Check out this amazing chair from Tom Dixon Studio in the UK.

10. Aluminium curtain wall

By far and away the largest use of aluminium is in the construction of curtain walls – these are the giant skyscraper sized walls of glass and grid that populate our cities. Without aluminium these structures would simply be too heavy. They’re essential for keeping out the rain and weather, reducing building sway, increasing energy efficiency – and of course they look fantastic and are highly versatile in the hands of talented architects.